Our business: Prefabricated rubber membranes

The advantages of welding by hot vulcanisation

In order to provide you with a perfectly waterproof membrane all the welding is done in the factory by hot vulcanisation. Manufacture by hot vulcanisation is the most qualitative technology for producing a weld between two elastomers.

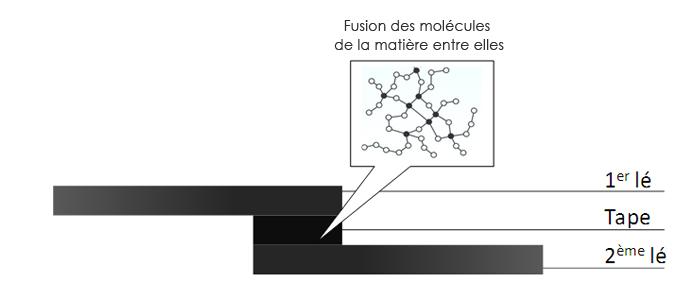

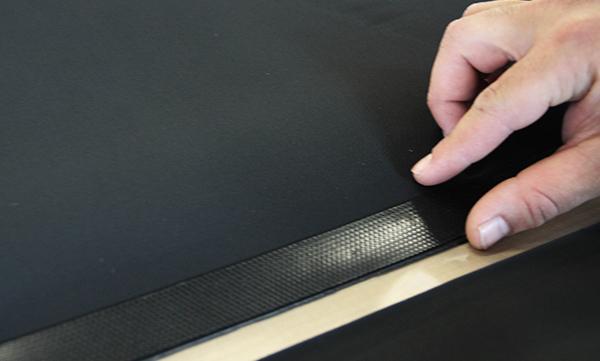

We place two panels one on top of the other and then insert a band of tape (crude EPDM) which will make it possible to perform the vulcanisation by cross-linking (fusion interlinking the material molecules).

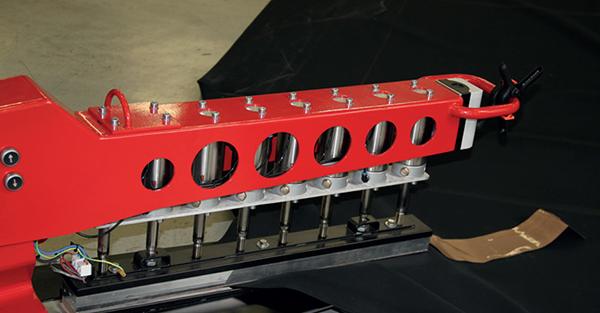

The assembly is pressed automatically by a robot to obtain perfect, indestructible and controlled welding, thus creating a perfectly waterproof, ultra-resistant assembly. After vulcanisation the assembly becomes a single, homogeneous material both physically and chemically.

- Ultra-resistant, indestructible assemblies

- Perfect waterproofing, 100% guaranteed.

- Perfect homogeneity between the various panels making up the finished product

- Mechanical resistance of the original sheets reinforced by the total cross-linking (fusion) of the material in the welds.

Welding by hot vulcanisation